VSF Material Conveying System

VSF Material Conveying

System

Our conveying system is designed to efficiently transport print pellets from the dryer to the extruder, ensuring a smooth and continuous feed for optimal 3D printing performance. By automating the material delivery process, the system minimizes material handling errors and maintains consistent quality throughout the production cycle. It ensures that the pellets are delivered in the right quantity and at the right time, preventing interruptions and reducing the risk of contamination.

Key Features and Benefits:

- Automated material transport: Seamlessly delivers pellets from the dryer to the extruder, ensuring continuous production.

- Consistent feed: Maintains a steady flow of pellets for smooth extrusion and high-quality printing.

- Minimized handling errors: Reduces manual intervention, lowering the chances of contamination or material waste.

- Energy efficient: Optimized to reduce energy consumption while maintaining performance.

- Customizable: Can be tailored to different printer setups and material types.

Our conveying system is designed to efficiently transport print pellets from the dryer to the extruder, ensuring a smooth and continuous feed for optimal 3D printing performance. By automating the material delivery process, the system minimizes material handling errors and maintains consistent quality throughout the production cycle. It ensures that the pellets are delivered in the right quantity and at the right time, preventing interruptions and reducing the risk of contamination.

Key Features and Benefits:

Automated material transport: Seamlessly delivers pellets from the dryer to the extruder, ensuring continuous production.

Consistent feed: Maintains a steady flow of pellets for smooth extrusion and high-quality printing.

Minimized handling errors: Reduces manual intervention, lowering the chances of contamination or material waste.

Energy efficient: Optimized to reduce energy consumption while maintaining performance.

Customizable: Can be tailored to different printer setups and material types.

VSF Drying System

VSF Drying System

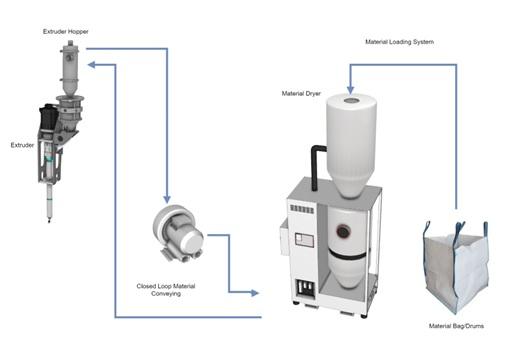

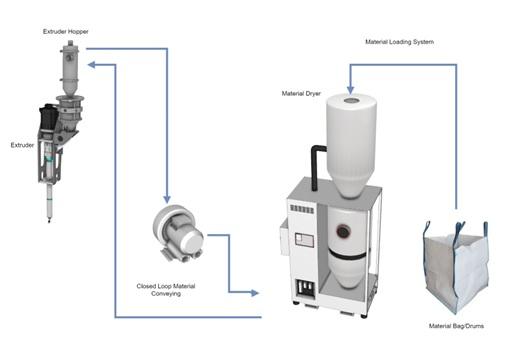

The VSF Composite print system schematic is shown below. It includes pellet drying system, pellet conveying and extrusion. Actual components may vary slightly from components shown below.

The VSF Composite print system schematic is shown below. It includes pellet drying system, pellet conveying and extrusion. Actual components may vary slightly from components shown below.

VSF Dryer:

- High efficiency

- Low energy plastics dryer suitable for a wide range of material

VSF Dryer:

High efficiency

Low energy plastics dryer suitable for a wide range of material

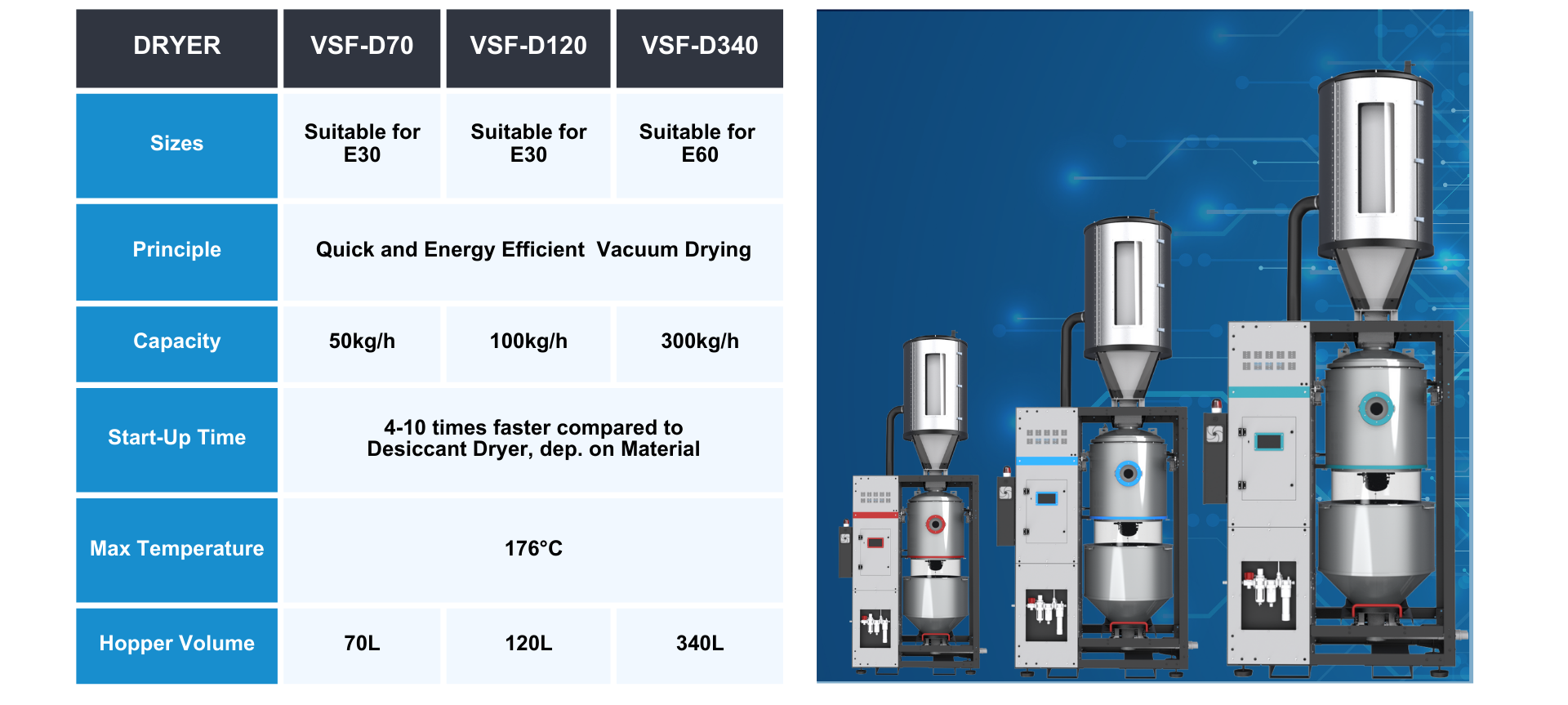

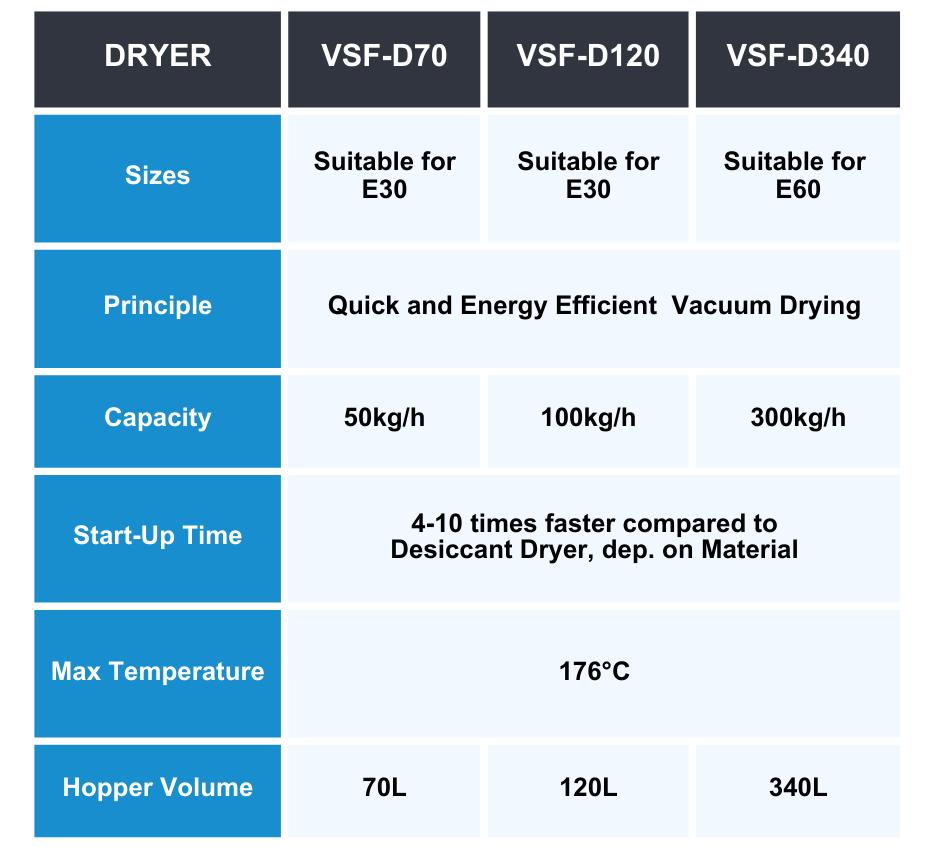

Many materials used for printing are hygroscopic and need drying prior to the print to ensure first class results.

VSF machines integrate an energy efficient vacuum drying technology that guarantees excellent results for a big range of materials covering different drying requirements. Depending on the required capacity, different models are available.

Key benefits:

- Unique energy efficient vacuum drying technology

- Fast return on invest due to very low drying costs

- Faster drying, faster start-up, minimal maintenance

Many materials used for printing are hygroscopic and need drying prior to the print to ensure first class results.

VSF machines integrate an energy efficient vacuum drying technology that guarantees excellent results for a big range of materials covering different drying requirements. Depending on the required capacity, different models are available.

Key benefits:

Unique energy efficient vacuum drying technology

Fast return on invest due to very low drying costs

Faster drying, faster start-up, minimal maintenance

Want to know more?